Precision engineering. High-performance results.

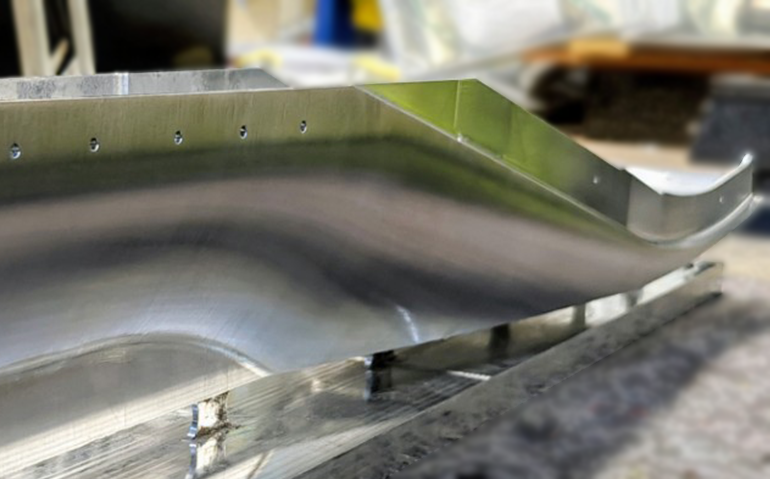

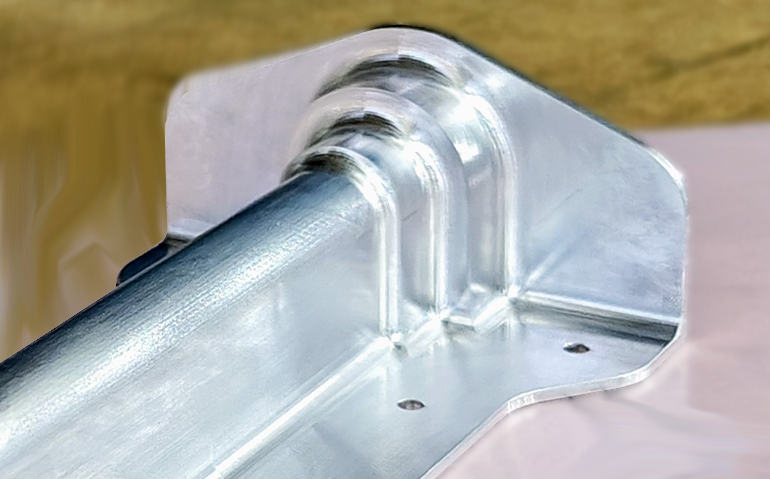

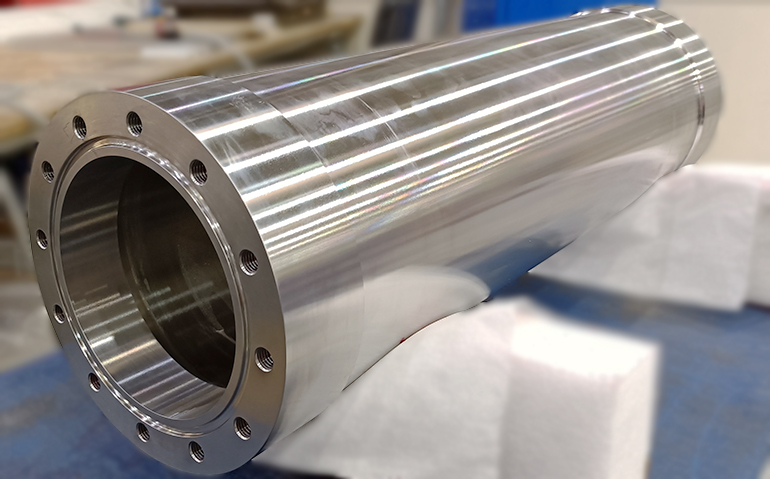

EDM offers subcontract 3, 4 and 5 axis complex machining delivering high-precision components with reliability and a level of quality that stands out. Our investment in people, equipment and processes is ongoing, expanding our capacity and capabilities to support demanding customers in the Defence, Space, Civil Aerospace & Rail markets.

Our mechanical and electrical design teams work on bespoke test rigs integrating complex systems, capabilities that come from our own synthetic training products and decades of experience. We are agile specialising in batches of critical parts or precision assemblies and maintain strict control over quality and lead time, from the statement of work or CAD data to final inspection.

High Calibre Equipment. Trusted Performance

We have a mix of predominantly Mazak and Haas machines. Capabilities include Turning and Mill/Turn, Thread (Internal and External cutting) and Milling.

· Renishaw probing systems, Reduce set up times on complex parts and can combined with bespoke controller Macros resulting in accurate part and tool setup.

· Nikken high-rigidity tool holders, built for performance at high spindle speeds

· Lang workholding, efficient and reliable clamping with minimal setup

· High-performance tooling, including Kyocera, TaeguTec, MA Ford, Emuge Franken and WNT/Ceratizit

We machine a wide range of soft and hard metals, including:

· Carbon and stainless steels

· Alloy steels (including Ramax HH) and Inconel (625, 718, C263)

· Grade 5 (6AL-4V) Titanium

· Aluminium alloys, commercial and aerospace grades (7050).

5-Axis Capability & CAM Integration

We use Autodesk PowerMill for full 3- and 5-axis programming and cut simulation, enabling precise process control. Our digital process includes:

· CAD-based collision detection

· Full machine and tool simulation

· Live verification with machine-specific toolpaths

· Automatic 5-axis collision avoidance

· Integrated Renishaw on-machine inspection

This approach ensures the programming is correct before the first cut.

Certified Quality

EDM is certified and approved to manufacture parts and equipment used in the World’s most demanding and regulated industries. Our accreditations and affiliations include:

Quality & Industry Standards

• ISO 14001:2015 DOWNLOAD ISO CERTIFICATE

• ISO 9001:2015 Quality Management System DOWNLOAD ISO CERTIFICATE

• AS9100D Accredited DOWNLOAD AS9100 CERTIFICATE

• JOSCAR registered DOWNLOAD JOSCAR CERTIFICATE

• Airbus, Boeing, SCAC: approved cabin training equipment manufacturer

• FAA, CAA, EASA, DGCA, CAAC: equipment manufactured to these standards

• UK, USA, NATO: defence approved supplier

• BAE Systems, Rolls-Royce, Martin Baker, Lockheed Martin: approved supplier

• Cyber Essentials Accredited DOWNLOAD CYBER ESSENTIALS CERTIFICATE

• Cyber Essentials Plus DOWNLOAD CYBER ESSENTIALS PLUS CERTIFICATE

• Verified RISQS supplier DOWNLOAD RISQS CERTIFICATE

Civil & Defence Approvals

· Approved cabin training equipment manufacturer for: Airbus, Boeing, SCAC

· Compliant to international standards including: FAA, CAA, EASA, DGCA, CAAC

· First Tier Supplier to: UK Ministry of Defence, US Department of Defence, NATO

Trusted by Leading OEMs

· Approved supplier to: BAE Systems, Rolls-Royce, Martin-Baker, Lockheed Martin, Capita, ARA, Collins Aerospace.

· EDM is a supplier of commercial aircraft cabin training equipment to many of the World’s airlines.

EDM designs and manufactures bespoke, high-performance training simulators for the civil aviation, defence, and rail sectors.

Our solutions range from full-scale cabin crew trainers and maintenance rigs to fire & smoke devices and advanced rail simulators, all built for realism, safety, and durability.

Trusted by organisations worldwide, we deliver training technology that prepares people for real-world performance.

40+

COUNTRIES WITH EDM DEVICES

250+

DEVICES MANUFACTURED

70+

COMPANIES WITH EDM DEVICES